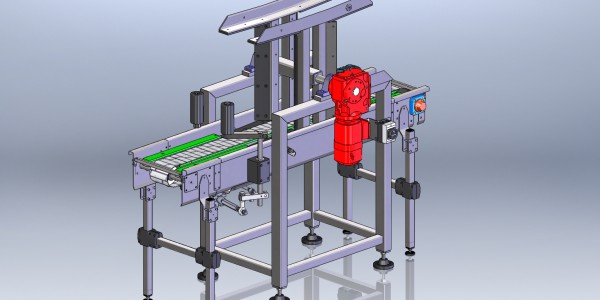

Robo Turn

After unloading the kegs from their pallets, the selective turning system automatically detects the neck of the keg (up or down) and turns them upside down to enable the washing/filling process. After the filling (head down), the kegs are turned spear up to be loaded on the pallet.

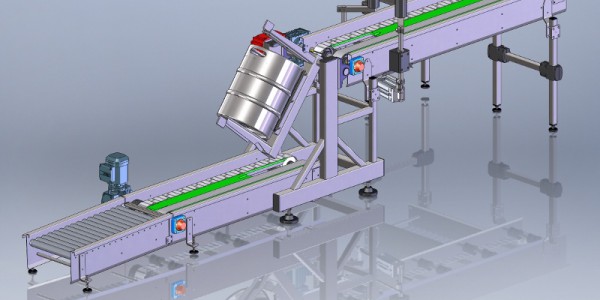

Two Level Turner

The two level turner enables empty kegs to be put onto and full kegs to be taken from a keg line in an ergonomically efficient way.

After filling, the two level turner detects the arriving keg on the conveyor, swings it around and delivers the keg on the ground level. After which, it can easily be palletized (by hand) at ground level.

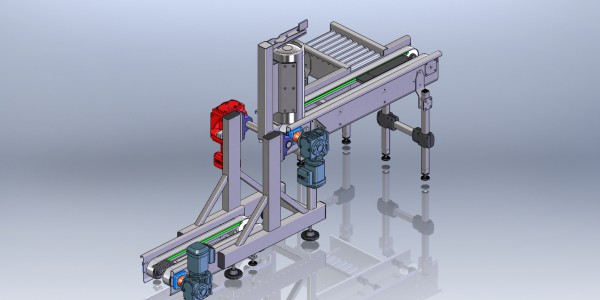

The X-Turner

The x-turner is capable of turning either full or empty kegs,

capacity 300 kegs/hour in 20, 30 and 50 l kegs.

Functioning

Capacity

– 800 kegs/h, single

– 1200 kegs/h, double

– Automatic adjustment for all keg types (max. 36 Gal.)

– Turns full and empty kegs

– Supplied with 3 mtr conveyor (drive excl.)

– Low noise level

– PLC operated

Option

– neck detection and selective turning