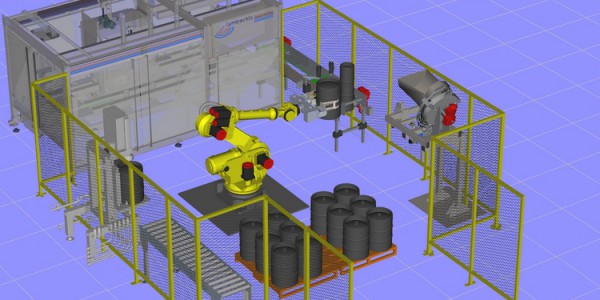

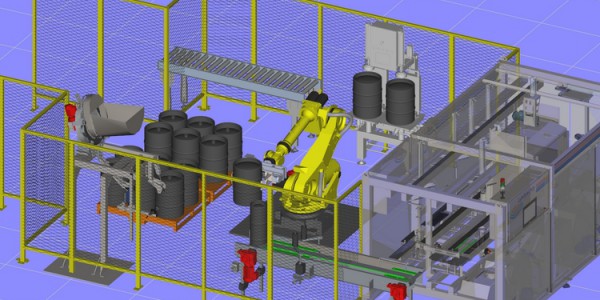

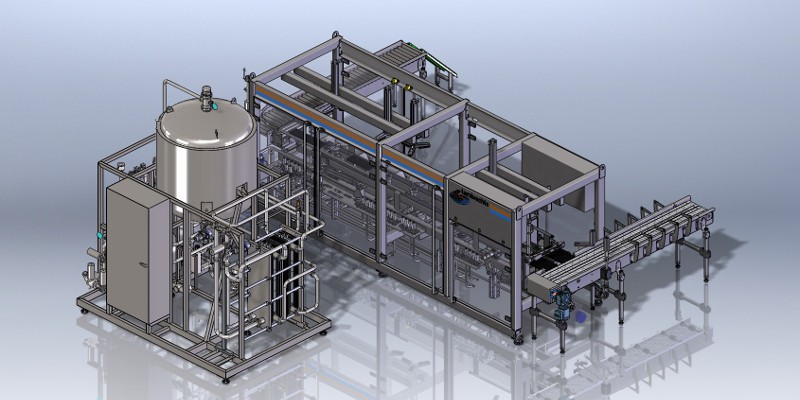

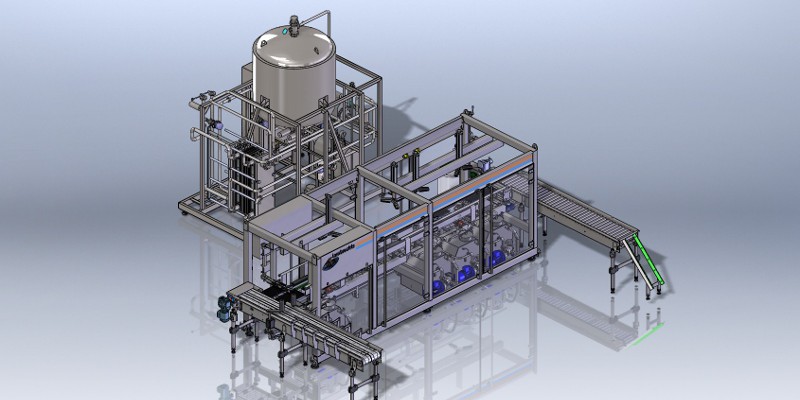

Project Description

Customer: Odell Brewery

Location: Fort Collins USA

Kegs per hour: 144-160 kegs/h, double Chunnel 422

Year Completed: 2016

“In 2014 we began researching keg line manufacturers that met our standards for keg cleanliness, robustness of design and service support. Lambrechts commitment to quality, support and overall systems design was very thorough, and demonstrated a long history of understanding effective keg sterilization. The more we grow to know the team at Lambrechts, the more we trust their leadership. Overall, I could not be more pleased with our keg line, the partnership and cultural fit between Odell Brewing Co. and Lambrechts.”

_John Baise_Packaging manager_Odell Brewing Co.